42 steam boiler piping diagram pdf

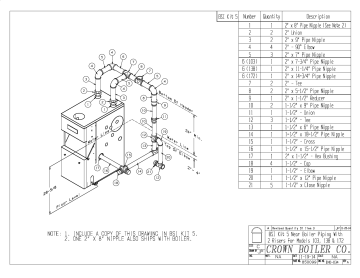

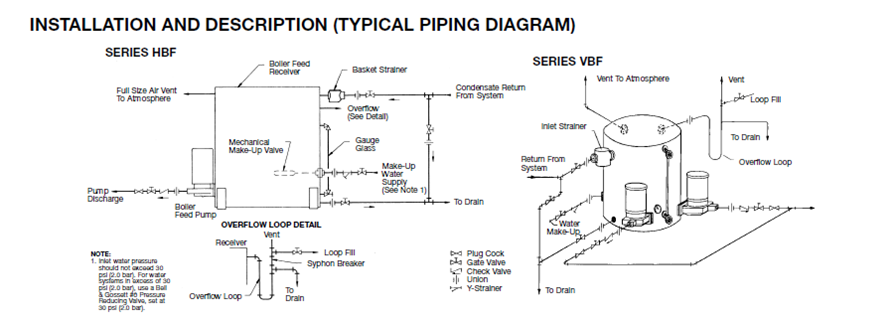

PDF V9A Series PIPING RECOMMENDATIONS - Burnham Commercial Boilers PIPING RECOMMENDATIONS WATER AND STEAM NOTES: 1. All piping is schedule 40. 2. Pipe sizes listed are based on a 20°F or 40°F differential (temperature drop). Select one to match application. Consult factory if boilers are used in low temperature applications or blending/mixing devices. 3. When specified return piping size is less than 3 ... PDF Blowdown System - Flexible Water Tube Boilers from Bryan ... Recommended piping diagram for Automatic Surface Boiler Blowdown System* Item Qty. Description 1 1 Gate valve 2 1 Motorized valve * For Bryan AB, CLM, DR, F, K, RV and RW Series Boilers * For Bryan AB, CLM, DR, F, K and RV Series Boilers NOTE: Available for RW Series, but requires additional piping.

PDF Installation and Operating Service Manual - Bryan Steam piping must be the same size as the relief valve discharge opening. Avoid over-tightening as this can distort valve seats. All piping from relief valve must be independently supported with no weight carried by the valve. 1.4.5 BLOWDOWN CONNECTION Blowdown valve(s) must be full size of the connection on the boiler. Steam boilers 15 psig and

Steam boiler piping diagram pdf

PDF U.S. Department of Veterans Affairs Standard Steam Boiler Plant Piping Diagram Author: Department of Veterans Affairs, Office of Construction and Facilities Management, Facilities Standards Service Subject: Standard Details Created Date: 10/7/2020 2:22:24 PM PDF INSTALLATION AND OPERATION MANUAL - BoilerData.com When opening any drains on the equipment or piping system, steps should be taken to avoid scalding/ burning of personnel due to hot fluids. Whenever possible, the system should be cooled prior to opening any drains. Post these instructions in an appropriate place near the equipment and maintain in good legible condition. WARNING cleaver brooks steam boiler piping diagrams - best boiler ... 1. WNS series gas & oil horizontal steam boiler 1-20 ton/hour, hot water boiler 0.7-14MW 2. SZL series chain grate boiler: 4 ~ 35 T/h steam boiler, 1.4 ~ 14 MW hot water boiler;

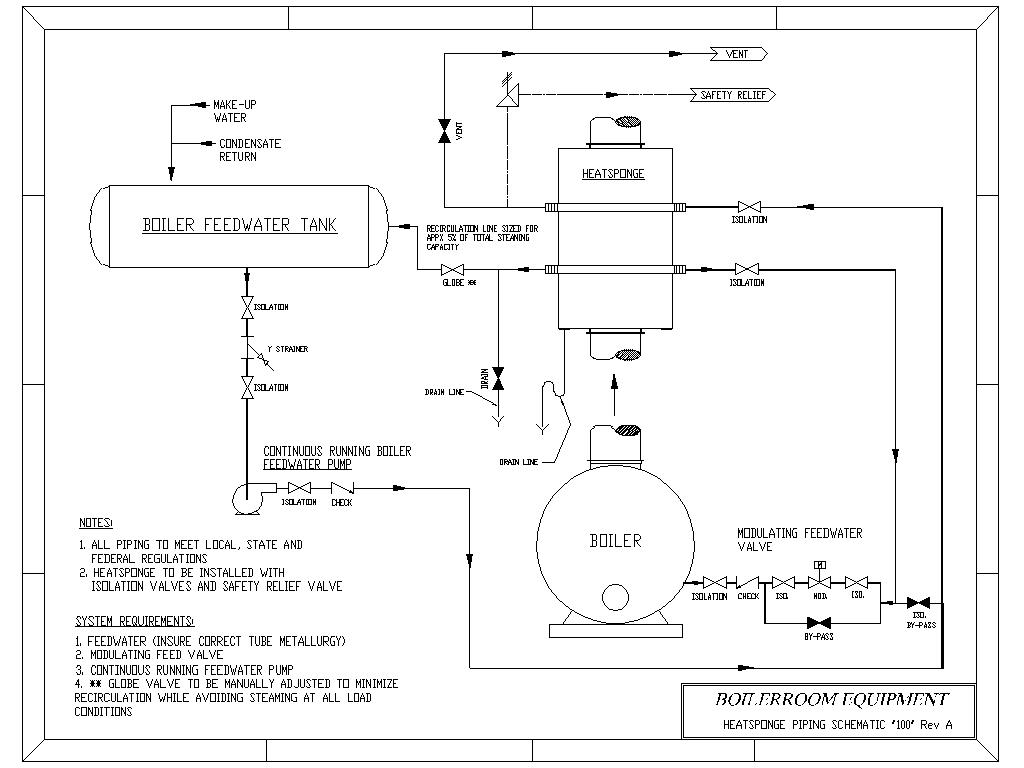

Steam boiler piping diagram pdf. PDF ENGINEERING MANUAL Industrial Boilers Referring to the diagram below, the circulation pump has to be sized to the pressure and temperature in the boiler, which can easily be 20 bar and 170°C. Because of this, economisers featuring air-cooled top and bearing flange may be required. PDF I. Piping Diagrams 13. Wire the tank or system/pipe sensor connected to the DHW sensor terminals on the follower boiler addressed as #1. 14. The system/pipe sensor must be placed on common piping to the tank, as close to the tank as possible. 15. The system/pipe sensor is wired to the system sensor terminals on the master boiler. PDF FULL-COLOR TRAINING GUIDE SERIES - PB Heat: Peerless® Boilers SIZING THE BOILER 1. The boiler output must be large enough to satisfy all connected radiators. 2. Size the boiler by doing a radiator count, totaling all of the connected Square Feet. 3. Select a boiler with a Steam Net Load Rating (in square feed of EDR) greater than the total connected radiation. 4. PDF INSTRUCTION MANUAL - Rite Boiler 2. Rite Atmospheric Boilers must be installed on a level, concrete housekeeping pad or other approved non-com-bustible surface that has been engineered to support the boilers operating weight. If installed on an open metal grate mezzanine, cover the area under the boiler with sheet metal to prevent excess air from coming directly

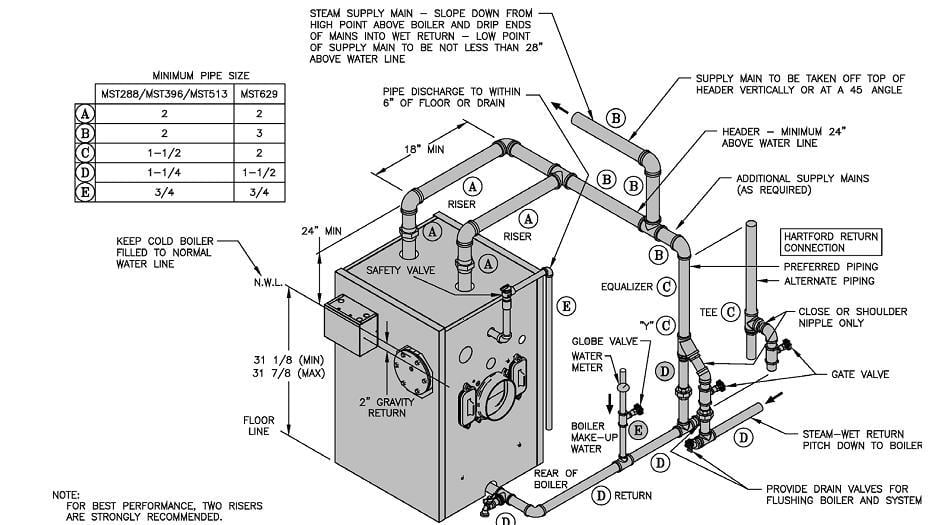

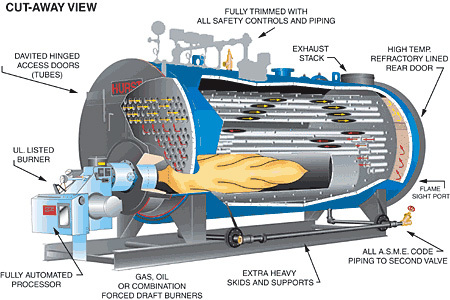

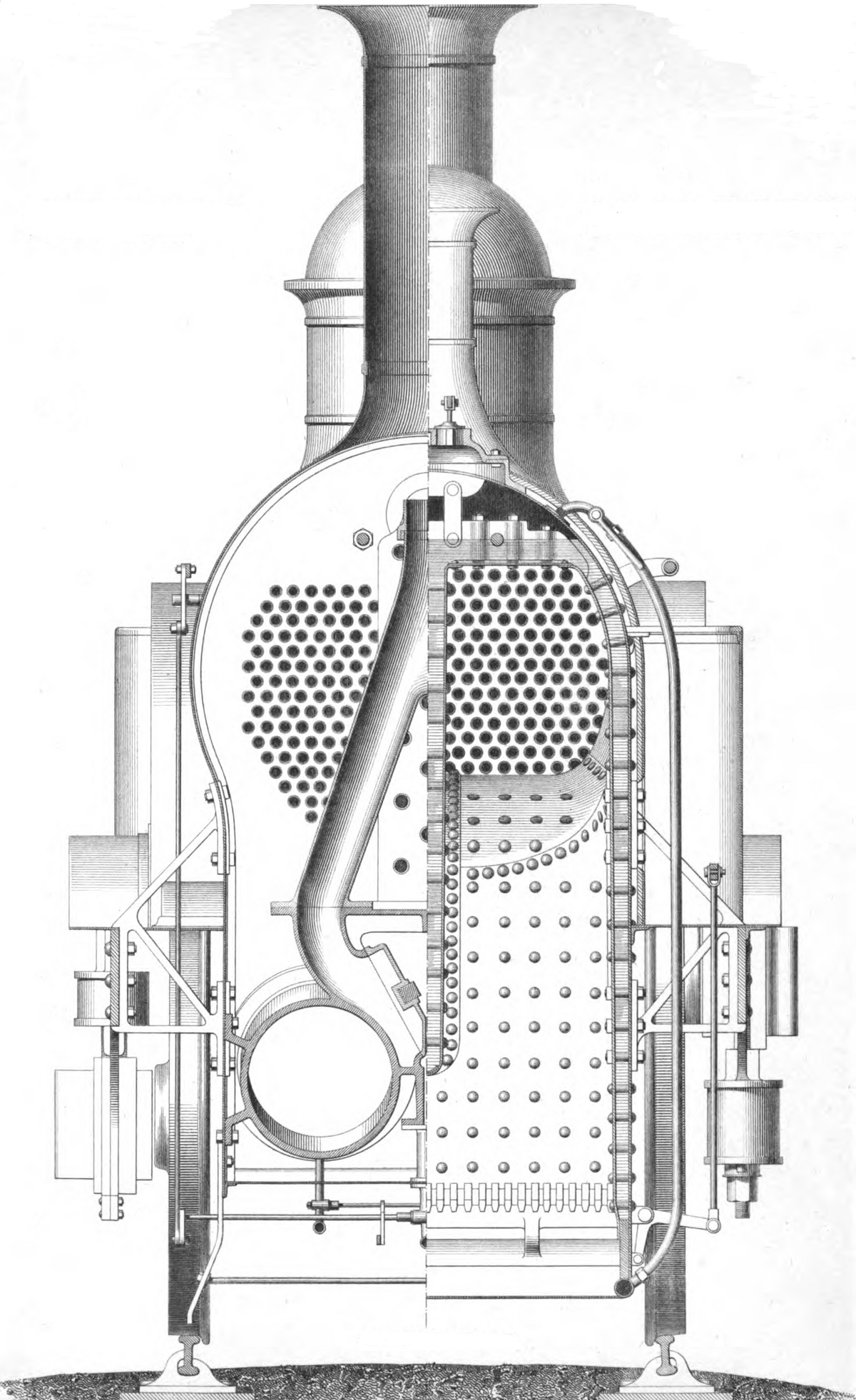

PDF Burnham Heating Helper Table of Contents CONDENSATE RETURN RISERS (Vertical, Horizontal Pitch) Capacity Based on Sq. Ft. (E.D.R.) (2 oz. PD per 100') Pipe Size Dry Return 3/4" 170 1" 410 1¼" 890 1½" 1,350 ONE PIPE STEAM 1. PDF Thermodynamic Design of a FireTube Steam Boiler Our engineering team designed a threepass fire tube steam boiler with a capacity of 5000 kg of steam per hour and a operating pressure of 10 bar. The Figure below equations shows a standard three pass fire tube steam boiler system used as a template for our engineering team's design. PDF Design of Boilers Piping - National Board of Boiler and ... Design of Boilers and Power Piping Section I PG‐58.3 Boiler External Piping • The Code Jurisdictional Limits of the boiler external piping systems are shown in Figure PG‐58.3.1. • The materials, design, fabrication, installation and testing shall be in accordance with B31.1, Power Piping. Steam Boiler Piping Diagrams Oct 27, 2019 - Are you looking for steam boiler diagram pdf pdf, word document or powerpoint file formats for free? Then you already in the right place. Find any . Standard Steam Boiler Plant Piping Diagram - Veterans Affairs. 1 Nov 2020 DO NOT SIZE VENT PIPES FROM BOILER SAFETY VALVES. CONTRACTOR MUST DO THIS. BASED ON VALVES FURNISHED. )- T-. ...

PDF Utica Boilers | American Made Gas and Oil-Fired Boilers Utica Boilers | American Made Gas and Oil-Fired Boilers PDF Chapter 14 Boilers - Pearson 292 Chapter 14 Stack—an opening at the top of the boiler that is used to remove flue gas, p. 297. Steam drum—the top drum of a boiler where all of the generated steam is collected before entering the distribution system, p. 293. Steam trap—a device used to remove condensate or liquid from steam systems, p. 294. Superheated steam—steam that has been heated to a very high temperature so ... Burnham Steam Boiler Piping Diagram - schematron.org Attached are the photos. Burnham Steam Boiler Piping Diagram Jan 7, In October, my 30+ year old steam gas boiler was replaced (had corrosion and leaking gas) with a Burnham Independence Steam boiler. It is common and acceptable practice to install these boilers in lower pressure systems, below the boiler MAWP. PDF STEAM BOILERS - Slantfin VENT PIPING— A. Vent piping installation must be in accordance with ANSI Z223.1-latest edition, National Fuel Gas Code, Part 7, Venting of Equipment. Other local codes may also apply and must be followed. B. Boiler vent pipe must be the full diameter of the boiler draft hood outlet. See dimensions, page 2. If a vent damper is

Boiler Manuals and Wiring Diagrams for Columbia Boiler Co ... WL60 Series waste oil boiler manual WIRING DIAGRAMS Most of the wiring diagrams are for natural gas powered steam boilers. Wiring diagrams for oil burning and water boilers are noted. CT 6, 10, 15 and 25 boiler wiring diagram CT 6 and 25 boiler wiring diagram CT 35 and 50 boiler wiring diagram HRT 20 and 30 boiler wiring diagram

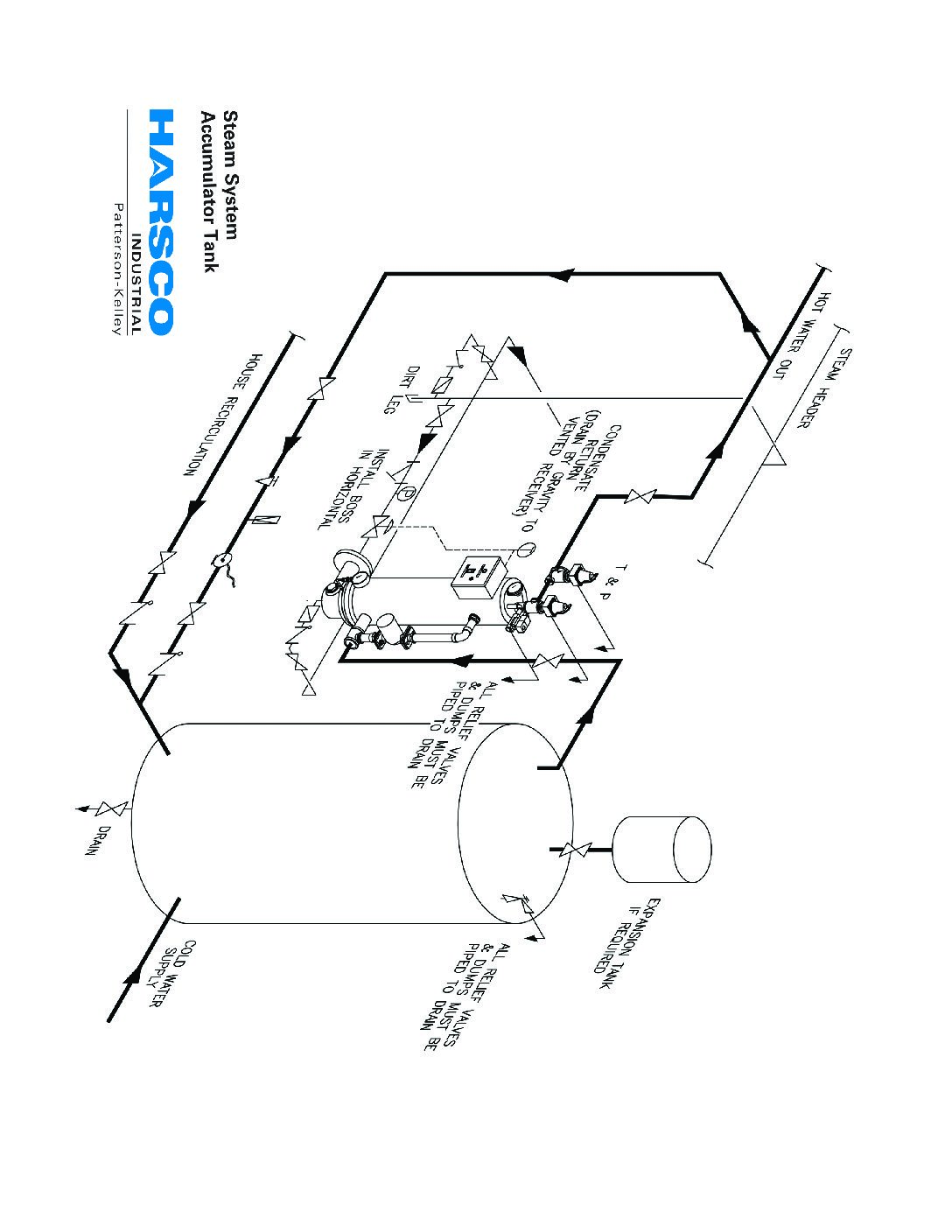

PDF Multiple Boiler Piping Diagram - Lochinvar, LLC multiple boiler - primary/secondary piping crest . from system relief valve hot water generator water generator circulator boiler drain (typical) boiler pump (typical) ball valve (typical) air seperator drain port (typical) system circulator to system make up water back flow preventer pressure reducing valve pressure

PDF Boiler Manual • Installation • Maintenance • Startup • Parts BEFORE installing, read all instructions in this manual and all other information shipped with the boiler. Perform steps in the order given. Failure to comply could result in severe personal injury, death or substantial property damage. • Installation • Startup • Maintenance • Parts Boiler Manual Part number 550-141-829/0316 Oil-Fired Steam Boilers

PDF An Introduction to Treatment of Steam Boiler Water A steam boiler is an enclosed vessel that holds water and is heated by an external source that converts the water to steam. All steam boilers contain tubes that separate the water from the heat source. Steam boilers are described in this publication. 1.1.1 TYPES OF STEAM BOILERS. Boilers are classified by two criteria: 1) operating

PDF Steam Near Boiler Piping Kits - PB Heat: Peerless® Boilers All near boiler piping including Hartford loop connections Part Number Steam Boiler Model Numbers 63910 63-03L & 63-03 63911 63-04L & 63-04 63912 63-05L Through 64-07 Now Available! Near Boiler Piping Kits for Peerless® Series 63/64™ Gas-Fired Steam Boilers. Save time and money with one complete piping kit. Kits contain

PDF Gas-fired Steam Boilers LOCATING THE BOILER Locating the Boiler 1. Select level location as centralized with piping system, and as near chimney as possible. 2. Place crated boiler at selected location. Remove all crate material. Please recycle responsibly. WARNING Fire hazard. Do not install boiler on combustible fl ooring or carpeting.

PDF Typical Piping for Conventional Single Boiler Installation ... application type diagram see installation manual for complete instructions. install in accordance with all local codes. typical piping for conventional single boiler installation lb-500, lb-750, lb-1000 • safety relief valve setting should not exceed pressure rating of any component in the system. • piping should conform to local codes.

PDF System Diagrams - Central Boiler System Diagrams H C M R Water Heater Hot Supply from Outdoor Furnace Return 10 gpm 10 gpm 10 gpm 5 gpm 5 gpm Bleeder Screw 4 x Pipe Dia. Max. Zoning Pump Multi-Heater Option Water-to-Water Heat Exchanger Hot Supply from Pump on Outdoor Furnace This horizontal assembly must not exceed a height of 4 inches above top of water heater.

steam boiler piping diagram - Boiler Sale 1. See recommended piping diagrams at the back of this manual, pages 47 to 51. 2. Do not reduce the steam boiler outlet nozzle size. Reducing the diameter of. Jul 14, 2015 - Steam doesn't care about heat loss or anything else-only the amount of the length of piping. If the boiler is too small, part of the building will.

steam boiler piping diagram - Industrial Autoclave ... Piping Diagram - Cemline. CEMLINE® has made a series of typical piping arrangements for the Model Series: USG High Temperature Hot Water Fired Steam Generator - PDF or DWG. A Hartford Loop is an arrangement of piping between a steam boiler's header and its gravity-return piping. The end of the header drops vertically below the.

PDF Cleaver-brooks 750-94 (revised 2009) Model CB, CB-LE Packaged Boiler Manual i Model CB, CB-LE Packaged Boiler 750-94 Table of Contents CHAPTER 1 Basics of Firetube Operation 1-1 1.1 — Introduction 1-1 1.2 — The Boiler 1-4 1.3 — Construction 1-5 1.4 — Steam Controls (All Fuels) 1-6 1.4.1 — Operating Limit Pressure Control 1-6 1.4.2 — High Limit Pressure Control 1-7 1.4.3 — Modulating Pressure ...

cleaver brooks steam boiler piping diagrams - best boiler ... 1. WNS series gas & oil horizontal steam boiler 1-20 ton/hour, hot water boiler 0.7-14MW 2. SZL series chain grate boiler: 4 ~ 35 T/h steam boiler, 1.4 ~ 14 MW hot water boiler;

PDF INSTALLATION AND OPERATION MANUAL - BoilerData.com When opening any drains on the equipment or piping system, steps should be taken to avoid scalding/ burning of personnel due to hot fluids. Whenever possible, the system should be cooled prior to opening any drains. Post these instructions in an appropriate place near the equipment and maintain in good legible condition. WARNING

PDF U.S. Department of Veterans Affairs Standard Steam Boiler Plant Piping Diagram Author: Department of Veterans Affairs, Office of Construction and Facilities Management, Facilities Standards Service Subject: Standard Details Created Date: 10/7/2020 2:22:24 PM

Comments

Post a Comment